Regenerative Scaffold Development Using Additive Manufacturing Techniques

In this project, we seek to use current additive manufacturing techniques to develop scaffolds for soft tissue replacement and regeneration. Our group has particular interests in spinal biomechanics and tissue characterization. Low back pain is a ubiquitous condition in the United States and can lead to long-term incapacitation. The pain generators in the lumbar spine are commonly identified as being associated with the facet joints and the intervertebral disc. Discogenic pain usually evolves from posterolateral damage to the annulus fibrosis, allowing the nucleus pulposus to herniate and exert pressure on the spinal cord and/or associated nerve roots. Surgical intervention usually involves resection of the damaged annulus (i.e. micro or partial discectomy) and/or complete annulus removal with an associated fusion between adjacent vertebrae. While both of these procedures may provide acute treatment for the associated myelopathy and pain relief, the former does not inherently arrest or reverse the underlying degeneration, while the latter significantly alters the physiological spinal load distribution, resulting in degeneration to adjacent vertebral segments. Therefore, our group is focused on developing new technologies and/or treatments that seek to regenerate the damaged intervertebral disc after the damaged annulus tissue has been removed.

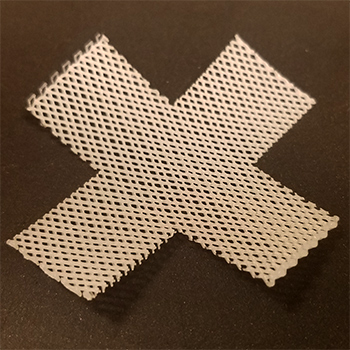

3-D printed scaffold in a cruciform shape to enable biaxial testing.

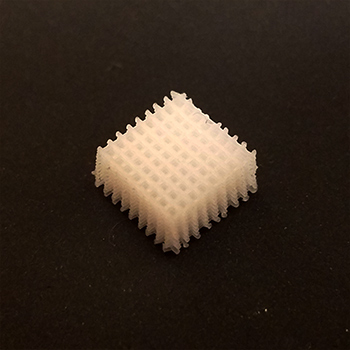

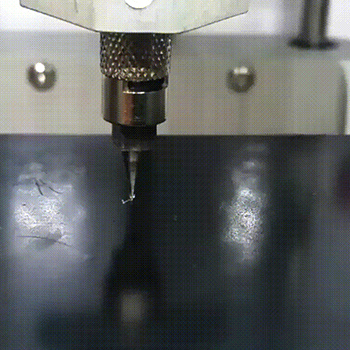

We use an extrusion method to produce PCL scaffolds with engineered fiber orientations.